Anti-Explosion Flashlight

A high-lumens and ATEX-rated right angle flashlight to be used in Zone 0 and mining locations.

Read More | UL CERTIFICATION Underwriters' Laboratories Inc. (UL) is an independent, not-for-profit product-safety testing and certification organization. They have been testing products for public safety for more than a century. In order for a product to bear the certified UL Mark, it must pass all UL requirements at their testing facility. |

| IECEx Certification The IECEx System is a certification system which verifies compliance with IEC international standards relating to safety in hazardous areas. It covers equipment, service facilities and the competency of personnel. |

| ATEX Certification The ATEX directive consists of two EU directives describing what equipment and work environment is allowed in an environment with an explosive atmosphere. |

| RoHS - Restriction of Hazardous Substances Directive Restriction of the use of certain hazardous substances in electrical and electronic equipment regulations implement by EU directive. |

| CE - European Conformity CE marking certifies that a product has met EU consumer safety, health or environmental requirements. |

Division 1 & 2:

A- Acetylene

B- Hydrogen

C- Ethylene

D- Propane

Zone 0, 1 & 2:

llC- Acetylene, Hydrogen

llB- Ethylene

llA- Propane

Division 1 Where ignitable concentrations of flammable gases, vapors or liquids can exist all of the time or some of the time under normal operating conditions.

Division 2 Where ignitable concentrations of flammable gases, vapors or liquids are not likely to exist under normal oprating conditions.

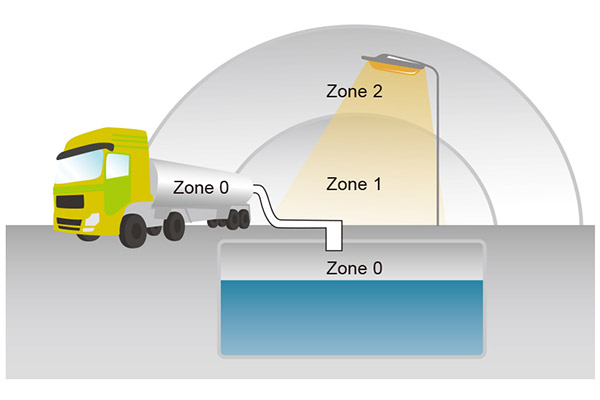

Zone 0 Where ignitable concentrations of flammable gases, vapors or liquids are present continuously or for long periods of time under normal operating conditions.

Zone 1 Where ignitable concentrations of flammable gases, vapors or liquids are likely to exist under normal oprating conditions.

Zone 2 Where ignitable concentrations of flammable gases, vapors or liquids are not likely to exist under normal oprating conditions.

| Groups | |

|---|---|

| Division 1 & 2: A - Acetylene B - Hydrogen C - Ethylene D - Propane | Zone 0, 1 & 2: IIC - Acetylene, Hydrogen IIB - Ethylene IIA - Propane |

Zone 20 Where combustible dusts or ignitable fibers and flyings are present continuously or for long periods of time in quantities sufficient to be hazardous.

Zone 22 Where combustible dusts or ignitable fibers and flyings are not likely to occur under normal operation in quantities sufficient to be hazardous.

Zone 0 Where ignitable concentrations of flammable gases, vapors or liquids are present continuously or for long periods of time under normal operating conditions.

Zone 2 Where ignitable concentrations of flammable gases, vapors or liquids are not likely to exist under normal oprating conditions.

Zone 21 Where combustible dusts or ignitable fibers and flyings are present continuously or for long periods of time in quantities sufficient to be hazardous.

| Groups | |

|---|---|

| Division 1 & 2: E - Metals - Div. 1 only F - Coal G - Grain | Zone 0, 1 & 2: None |

Division 1 Where easily ignitable fibers or materials producing combustible flyings are handled, manufactured or used.

Division 2 Where easily ignitable fibers are stored or handled.

Groups: None

| Temperature Codes | |

|---|---|

| US Classification T1 < 450 T2 < 300 T2A < 280 T2B < 260 T2C < 230 T2D < 215 T3 < 200 T3A < 180 T3B < 165 T3C < 160 T4 < 135 T4A < 120 T5 < 100 T6 < 85 | Europe Classification T1 < 450 T2 < 300 T3 < 200 T4 < 135 T5 < 100 T6 < 85 |

Recently, a need for a standard performance platform for the flashlight industry was recognized. The absence of a consistent performance standard has made it difficult to provide comparable product claims and effectively communicate features and benefits, which consumers use to select the right flashlight for their specific needs. Our research indicates a consistent performance platform would be quite beneficial to help users make the right selection when choosing a flashlight.

In addition, the category is changing rapidly as new companies and products enter the market. Flashlight technology has radically changed and consumers are eager to learn more about these new disruptive technologies.

Current agencies, such as UL (Underwriters Laboratories), do not provide performance standards for flashlights, so major retailer's that employ testing firms are requesting guidance.

To respond to this need, 14 flashlight companies, including Energizer, collaborated to write a standard. They included the following products: hand-held/portable flashlights, spotlights, and headlamps.

The ANSI/NEMA FL 1 Standard has been ratified and includes six measures. Each measure is defined, has a test procedure specified, and has an associated icon to use for claims. Standard ratification included voters representing three groups: 1) manufacturers, 2) users, and 3) general interests - one group cannot represent more than 50% of the total ratifying vote.

| Measure | Definition | |

|---|---|---|

| Light Output | Light Output is the total quantity of emitted overall light energy as measured in an integrating sphere system. The value is reported in lumens. |  |

| Runtime | Run Time is the amount of continuous runtime (in minutes), using new battery, until the light output drops to 10% of it's original value. The test is done in an integrating sphere just like the lumen test with light output measured every 15 minutes. |  |

| Beam Distance | Beam Distance is defined as the distance from the device at which the light beam is 0.25 lux ( 0.25 lux is equal to the light emitted from the full moon on a clear night in an open field.) |  |

| Peak Beam Intensity | Peak Beam Intensity is the light intensity measured in candela (cd) at the brightest part of the beam. A lux reading in the brightest portion of the beam is taken at some distance (2m, 10m, or 30m) with the light on its brightest mode and tightest focus at some time between 30 and 120 seconds of turning the light on. The lux reading is multiplied by the square of the distance in meters to get candela. |  |

| Enclosure Protection Against Water Penetration Ratings | Water resistant: "IPX4";. Light can be splashed with water from all directions without water getting inside. Water proof: "IPX7". The light can be submerged in 1 meter of water for 30 minutes. Water can leak into the light, but not into areas with electronics or batteries. The light must still operate when removed from the water and then is tested again 30 minutes after being removed. Submersible: "IPX8". The light can be submerged for 4 hours to some depth greater than 1 meter. The depth would be specified, e.g. IPX8 10 meters. Realistically the light is not put in the given depth of water, but instead is completely submerged in a container and the pressure is then increased to simulate the depth. |  |

| Impact Resistance | Impact Resistance is the height, in meters, from which the light (including batteries) can be dropped onto concrete without cracking or breaking and still function. Lights are dropped while in the Off position and allowed to come to rest before inspecting for damage. For ratings over 1 meter, each sample light is dropped six times with different faces towards the ground. |  |

A high-lumens and ATEX-rated right angle flashlight to be used in Zone 0 and mining locations.

Read More

Best Choice PPE offer a range of protective eyewear for hazardous working conditions. Welcome to our website...

Read More

The sport collection has catching design and comfortable wearing experience for daily outdoor active.

Read More